Decarbonizing our Operations

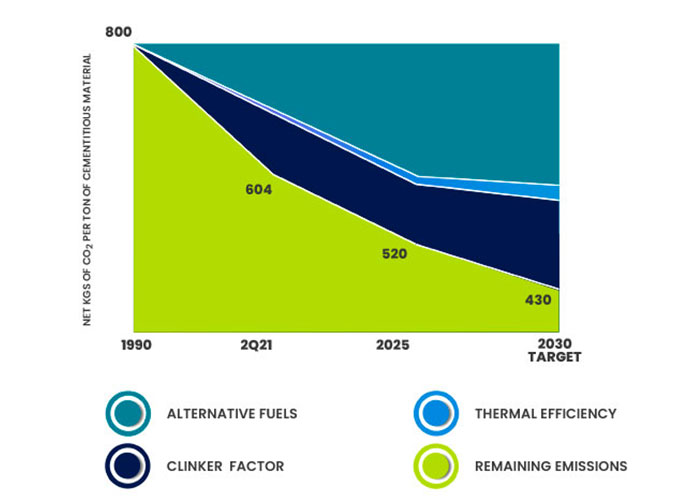

Future in Action concentrates on maximizing four levers to reduce our carbon emissions, and achieve our 2030 goals:

- Increasing the use of alternative fuels instead of regular fossil fuels.

- Reducing the clinker factor in our cement.

- Optimizing thermal efficiency in our kilns.

- Increasing the use of decarbonated raw materials in clinker.

Future in Action concentrates on maximizing four levers to reduce our carbon emissions, and achieve our 2030 goals:

- Increasing the use of alternative fuels instead of regular fossil fuels.

- Reducing the clinker factor in our cement.

- Optimizing thermal efficiency in our kilns.

- Increasing the use of decarbonated raw materials in clinker.

Alternative Fuels and Co-Processing

Alternative fuels can eliminate our reliance on fossil fuels, powering our kilns while also providing other benefits for the environment. Alternative fuels, particularly biomass, are a byproduct of humanity, which otherwise end up in landfills. The ensuing decomposition generates methane, a greenhouse gas up to 80 times more harmful to the environment than CO2.

Co-processing is a more efficient waste management solution than landfilling and incineration, this means that the cement industry is a net consumer of waste and contributes to a more Circular Economy.

There are four main benefits of co-processing for climate action:

Clinker Factor Reduction

Clinker, the key component of cement, is produced by fusing together limestone, clay, and other materials in a rotary kiln at temperatures nearing 1500 Celsius. This is a very energy-intensive and carbon-emitting process. In fact, most direct CO2 emissions in the cement production process are generated by the chemical reaction of clinker production in our kilns. Our efforts concentrate on substituting it with byproducts from other industries like blast furnace slag, and fly ash. Waste from other industries and alternative raw materials allow us to reduce the clinker factor while maintaining the same quality and durability of our products. Our new clinker types have up to 20% lower CO2 emissions.

In 2021 we achieved our best performance ever in the use of alternative fuels, clean electricity consumption, and the largest annual reduction in clinker factor in the last 10 years.